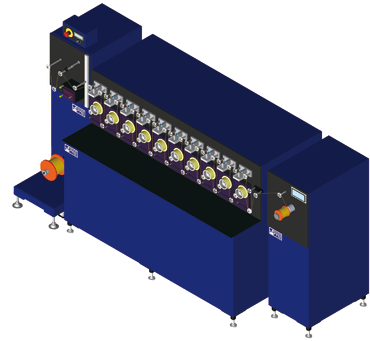

Non-Slip Type Wire Drawing Machine

Features

- Supports independent non-slip synchronized control of each capstan.

- Supports 1,000m/min drawing of thin wire (Au, etc.),

under ultra-fine condition. (-15µm) - Supports reverse tension drawing under ultra-fine condition. Reduces pressure to the die surface and pullout force.

- No restriction on mechanical reduction.

Adjusts automatically to given dies schedule . - Supports reducing the number of dies by setting high reduction values.

- Supports stable supply of back tension on each die by way of high-precision tension control. (Supported by variable load dancer roll.)

- Available attaching measuring system for a characteristic movement of die.

Supports real-time measurement / data management for reduction ratio and pullout force by tension detection unit and measuring system. - Available attaching Auto-traverse function.

- Supports real-time measurement of actual reduction of each die.

| Type | D3ULT-10D |

|---|---|

| Wire Materials | Au, Cu, Stainless steel, the other ultra-fine wires |

| Wire Diameter | φ0.01mm~ |

| Spool Size | Max. Flange Diameter:φ160mm / Max. Overall Width:160mm |

| Tension | 0.5~7.0cN / 1.0~15.0cN / 5.0~35.0cN / 10.0~100.0cN |

| Traverse Pitch | ~1mm/rev |

| Traverse Width | ~160mm |

| Speed | ~1000m/min(MAX5500rpm) |

| Dimensions | L880 x W2900 x H1850 mm *Safety Cover Included |

| the Number of Dies | 10 |

*Select tension according to intended applications.

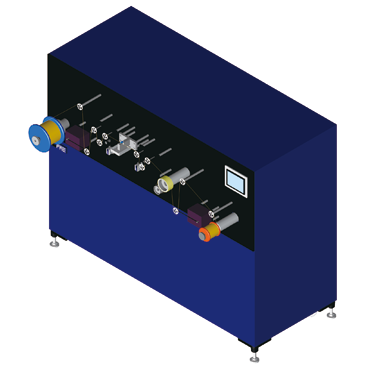

Die Measuring Wire Drawing Machine

Features

- Supports real-time measurement of back / front tension,

speed, and reduction. - Supports comprehensive evaluation by real-time measurement

of wire drawing. - Available as Die evaluation machine : including die shape/abrasion effects.

- Available for quality evaluation against lubricant solution effects.

- Available as Non-slip type One-Die Drawing Machine use.

- Customize available under request for target material and diameter.

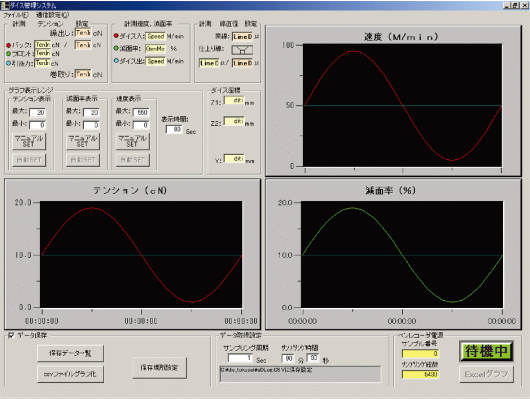

Measuring Items Articles

Direct measuring Articles

- Back Tension / Front Tension (by load cells)

- Wire entry/exit Speed into/out of a die

Computational measurement Articles

- Pullout Load

- Reduction

Supports automatic real-time graph/value indication of direct / computational measurement articles.

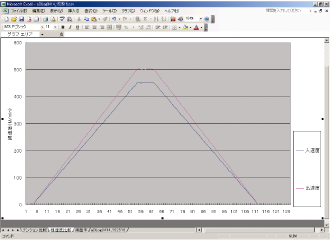

View of measurement system display

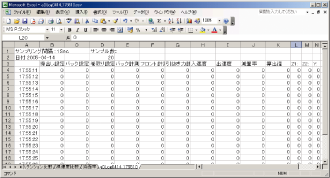

Data table (Outputted by Microsoft Excel)

Result data graph (Plotted by Microsoft Excel)